Sensors in robot

Robots use several types of sensors to give them a sense of touch, including:

- These sensors allow robots to interact with objects gently and monitor applications. They can detect touch and force, and are divided into two categories.

- These sensors use infrared light to detect when objects are close to the robot, giving it a sense of touch.

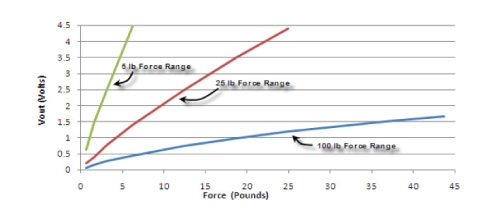

- These sensors detect the amount of force being applied, which helps keep the robot, products, and other objects safe.

- These sensors require physical contact to function, and are used in limit switches, button switches, and tactile bumper switches. They are often used to help robots avoid obstacles.

- Sound sensors: These sensors detect sound and convert it into an electrical signal. Robots can use this to navigate through sound, or to recognize and respond to specific sounds.

- Navigation and positioning sensors: These sensors help robots approximate their position. A common positioning sensor is GPS, which uses signals from satellites to help robots determine their location.

- Acceleration sensors: These sensors measure the acceleration and tilt of the robot.

What Are Robotic Vision Sensors?

A. A robotic vision sensor is a self-contained unit that can feature a combination of an integrated camera, lights and a controller (and sometimes a laser). Robotic vision sensors are designed for simple installation and operation. They are especially suited for straightforward operations, such as inspections on an assembly, that involve a yes-or-no, pass-or-fail answer.

Robotic vision sensors capture an image of an object with a camera and then calculate the characteristics of that object, such as its length, width, height, position and area. They perform tasks such as:

- Detect the presence or absence of parts

- Determine the orientation of parts

- Calculate the accuracy of parts

- Verify shapes

- Verify colors

- Recognize characters (words on a label, for example)

In this tutorial, we are going to make a light-chasing robot that moves toward areas of bright light. We will be using photoresistors to determine the brightness of the light. For a better understanding, have a look at the line following robot, surveillance robot car, obstacle-avoiding robot that we previously created.

A photoresistor, or photocell, is a light-dependent resistor (LDR). It acts just like regular resistors, but it responds to the amount of light detected. Using this property of the LDR we are going to make our robot using Arduino, the LDR module, and the L298N motor driver module. So let’s get started and built this robot.

For decades, industrial and service robots have relied predominantly on vision systems and inertial sensors to perceive and interact with the world around them. However, while necessary, these modalities lack a critical human sense – the sense of touch.

Robots equipped only with cameras and accelerometers cannot detect tactile physical forces, gather data on surface textures, or gain proprioceptive feedback on their movements and joint positions. Lack of tactile awareness severely limits their ability to handle objects dexterously, move adaptively through complex environments, and respond safely to physical contact.

Pressure sensors now provide robots with the vital tactile feedback needed to elevate their abilities. By continuously monitoring hydraulic and pneumatic pressures within robotic joints and actuators, pressure sensors give robots proprioceptive awareness of their own motion and torque exertion. This feedback enables advanced control of movements and the application of targeted joint forces.

Covering robot surfaces with flexible and conformable pressure sensor arrays creates an artificial sense of touch. The skin-like pressure-sensing layers allow robots to detect, map, and respond to external forces from contact, collisions, or human interaction.

Robots can achieve remarkable human-like dexterity and adaptability with sufficient pressure data integrated into control loops. Tactile pressure feedback brings robotics closer to safe and seamless collaboration alongside human coworkers in factory settings. It also opens up new horizons for robotics in high-risk environments like disaster response, defense, healthcare, and space exploration where blind automation is insufficient.

Comments

Post a Comment